AGS - Aerobic Granular Sludge Technology

AGS - Aerobic Granular

Sludge technology is an innovative biological treatment technology

with enhanced sludge settlability, nitrogen and phosphosrous

nutrient removal, less energy consumption compared to other

SBR - Sequencing Batch

Reactor technology and Activated Sludge Process.

AGS technology can be considered as SBR 2.0, which is largely

based on the SBR sequencing batch reactor process, and cultivates

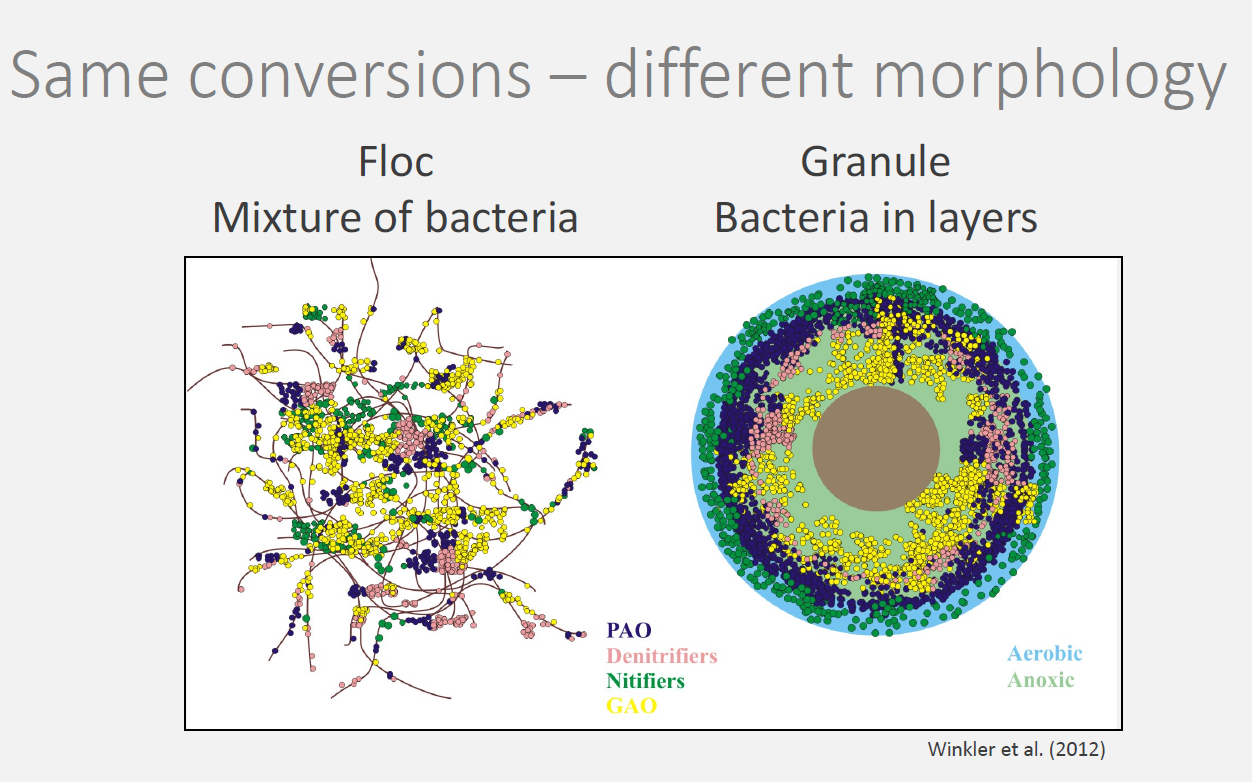

and utilizes the unique properties of the anaerobic-anoxic-aerobic

bacteria species in the granules, to achieve COD and nutrient

removal with lower aeration energy.

AGS (Aerobic Granular Sludge) Technology Advantages/Benifits

- Lower footprint and space requriements

- Reduced energy consumption - almost lowest energy

consumption besides MABR process

- Nutrient removal without chemicals - nitrification and denitrification,

phosphate removalSimultaneous nitrification and

denitrification, and able to achieve high level of N removal

- Phosphsphorous removal

- Tolerates wide swings in flow and organic loading

- No clarifier required (same as SBR)

- Better control over filamentous growth and settling problems

- Less equipment to service and maintain (compared to SBR:

no decanter, no mixer)

- Existing ASP or SBR plants can be converted to AGS

- No need to use bacteria or biofilm-supporting packing medium or solids-separation membranes

Wastewater Engineering Group provides AGS -aerobic granule

sludge

wastewater treatment plant and process design services, consulting,

retroffing and new plants.

- AGS Plant Design

- AGS Process Design

- Pilot Test

- Startup and Commissioning

- Equipment Supply and Servicing

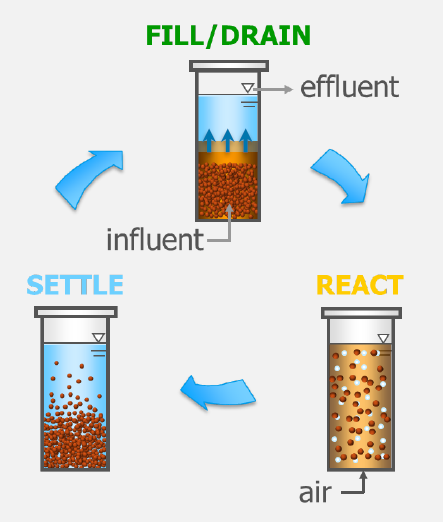

A process flow diagram of a typical AGS system is as shown above.

The processes inside the Sequencing Batch Reactor system include

the following:

- Fill/Draw - raw sewage or wastewater is filled into the SBR

tank, and it flows from bottom of the tank upwards to expell out

the supernatant on top of the tank, which is the treated waste

from previous batch. Anaerobic hydrolysis takes place during

this phase, and phosphate is released from the sludge into the

bulk liquid.

- React - aeration process for the carbonanceous organic pollutant

removal, in the meantime, ammonia is removed by nitrification

in the aerobic and anoxic layers of the aerobic granule.

Phosphate is uptaken by the PAOs (Phosphate accumulating

organisms) and removed from the bulk liquid.

- Settlement - settling of sludge after the react. The AGS

granules settles very fast and within 5 mins it has all settled

to the bottom of the tank.

Some major equipments used in Sequencing Batch Reactor System

are:

- Pretreatment equipment: bar rakes, coarse and fine screens

- Fine bubble aeration systems: air blowers and diffusers

- Pumps for raw wastewater and treated effluent pumping

- AGS sludge thickening, dewatering and further treatment

- Effluent disinfection systems

Wastewater Engineering Group offers integrated AGS wastewater

treatment plants /facility and process design, planning, for sewage

disposal and water reuse. |